Global (EN)

Global (EN)

Choose a different country or region to see the content specific to your location

Global (EN)

Global (EN)

Choose a different country or region to see the content specific to your location

How can we help you?

RunCare Standard service includes the basic maintenance RunEco EP Turbo Blowers require on a regular basis. One Runtech specialist can perform all services on site during a day.

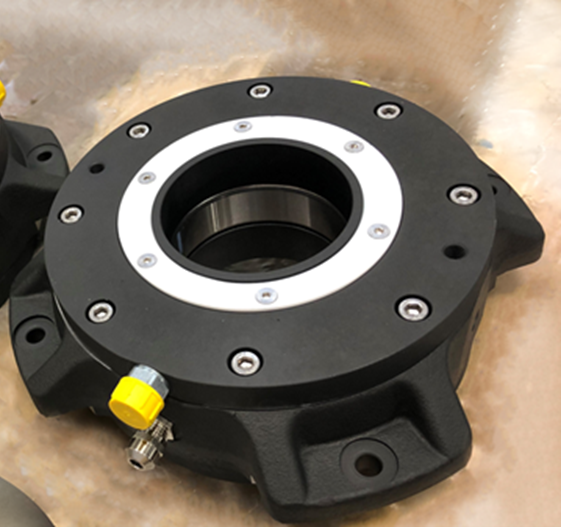

With high air flows and possible impurities from the process, the vacuum system operating conditions are harsh. The turbo blower impeller can become dirty and cause an imbalance. A dirty impeller also reduces turbo blower efficiency. Basic maintenance requirements for RunEco EP Turbo Blowers include a bearing unit exchange and washing of the impellers regularly, according to turbo blower model service plan.

In addition, oil and oil filters should be changed every four months. We recommend regular washing of the EcoDrop water separator lamellas and replacing the cooling air filter.

All service visits include a report and recommendations to keep the vacuum system in optimum condition.

Runtech Systems is a global provider of engineered systems tailored to the pulp and paper industries. Runtech works with customers to better understand and control their operational conditions to maximize efficiency and cost effectiveness. Our main target is to bring notable energy savings and highly improved process efficiency for board, tissue and paper mills.

Runtech's patented solutions include energy efficient vacuum system and heat recovery optimization, runnability optimization, dewatering, doctoring and cleanliness optimization as well as ropeless tail threading, including related services, spare parts and paper machine audits and consulting.