Choose a different country or region to see the content specific to your location

Global (EN)

Global (EN)

Choose a different country or region to see the content specific to your location

Global (EN)

Global (EN)

How can we help you?

Runtech Systems delivers RunEco vacuum system rebuilds to two Doruk Paper sites in Turkey. RunEco systems with EP650 and EP315 Turbo Blowers will provide vacuum for the Doruk Paper and Packaging Industry Inc. Kayabasi site paper machines PM1, PM2 and PM4. Doruk Kagit Sanayi ve Ticaret A.S. PM3 vacuum system will be rebuild with an EP650 Turbo Blower. Deliveries include also EcoDrop water separators and EcoFlow dewatering measurements for all four paper machines.

“Upgrading the vacuum systems will provide the mill not only energy savings but also flexibility. With our turbo blower technology, the turbo speed is automatically adapted to the needed vacuum level,” says Mario Battiston, Sales Manager, Runtech Systems.

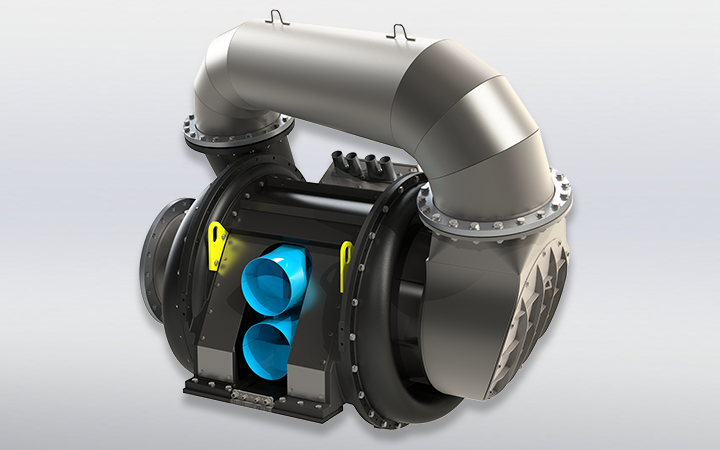

Environmentally friendly and energy efficient, RunEco vacuum system provides a reliable, completely water free vacuum solution. Less energy and no water contribute to lower CO2 emissions and smaller environmental footprint. EP Turbo Blowers are always variable speed and capacity, which allows the vacuum system to be optimized quickly without bleed air and with minimal throttling and expansion losses. With integrated high-speed motor controlled by a frequency converter, rotation speed and vacuum level can be adjusted according to the process requirements.

EcoFlow dewatering measurement provides accurate real-time feedback about the dewatering performance along the paper machine which can be used to optimize dewatering and vacuum levels in the forming and press sections.

About Doruk Paper

Doruk Kagit, founded in 1994 in Kayseri Organized Industrial Zone, produces recycled packaging and specialty papers on its four paper machines. Protection of nature is one of the most important principles of the company, which is creating recycling awareness in the country.

Read more about RunEco vacuum systems

Runtech Systems is a global provider of engineered systems tailored to the pulp and paper industries. Runtech works with customers to better understand and control their operational conditions to maximize efficiency and cost effectiveness. Our main target is to bring notable energy savings and highly improved process efficiency for board, tissue and paper mills.

Runtech's patented solutions include energy efficient vacuum system and heat recovery optimization, runnability optimization, dewatering, doctoring and cleanliness optimization as well as ropeless tail threading, including related services, spare parts and paper machine audits and consulting.